NTC thermistor is a temperature-sensitive semiconductor resistance with great reliability, good stability and long service life. With the development of the electronic technology industry, a variety of electronic products to further achieve multi-functional and intelligent, NTC thermistor in all kinds of needs for temperature monitoring, control, compensation and other occasions are increasingly used.

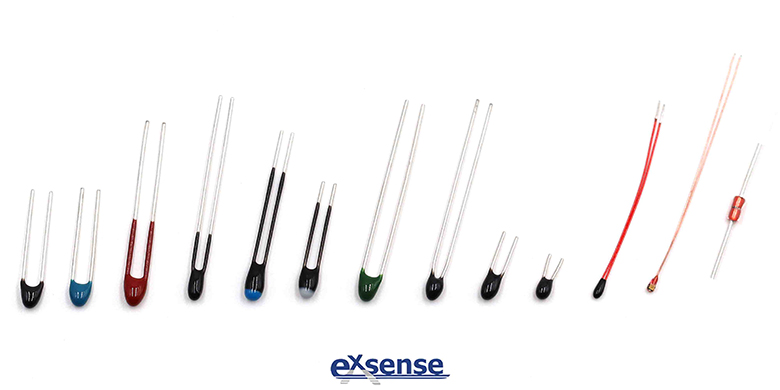

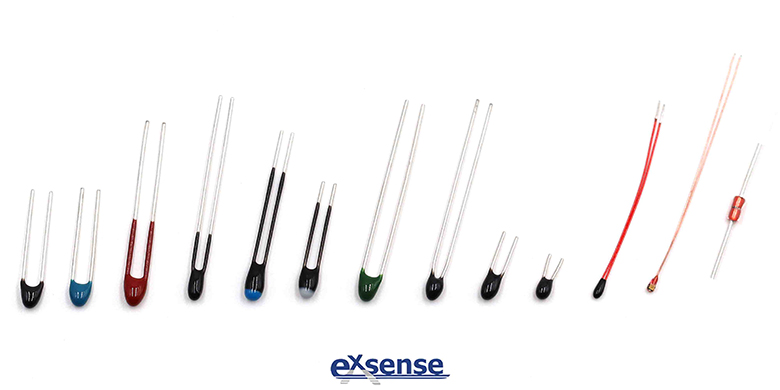

Glass sealed NTC thermistor is one of the conventional types of thermistors, which is mainly used for temperature compensation, can be suitable for harsh environment with high temperature and humidity, and the product is small and hard, can meet the application trend of temperature monitoring. Due to the glass sealed NTC thermistor plays a central role in converting temperature variables into the required electronic signals in the circuit, it is widely used in temperature control and measurement of home appliances (air conditioners, microwave ovens, heaters), etc.; Temperature detection of office automation equipment (copier, printer, etc.); Temperature control of industrial, medical, environmental protection, meteorological, food processing equipment, etc. However, the glass sealed NTC thermistor produced by existing technology and its production process have the following disadvantages:

First, as the glass head is very dense and brittle, it is easy to break and damage the glass head during product testing, manual operation and assembly process if the dumet leads are pulled and broken, resulting in reduced product reliability and performance variation.

Second, due to the easy damage in the production process, the product pass rate of existing glass sealed NTC thermistor is low, the pass rate of its resistance value within ±1% of the standard resistance value is only 50%~60%.

Third, the connected part of the glass head and the dumet leads is easy to rupture by external forces, which makes the product vulnerable to environmental impact in the process of use. Such as in a humid environment, water vapor from the glass cracks into the internal NTC thermistor chip, resulting in product resistance variation. If used in water, water will invade the internal thermal chip from the glass cracks, and eventually lead to poor electrical performance of the product, or even cause short circuit and burn out of the product.

Four, the space between the two dumet leads near the glass head is small, which is about 0.5mm and prone to short circuit during the assembly and use of the product, resulting in the failure of the electrical performance of the product. In serious cases, the NTC thermistor chip will be burned out, or even the equipment will be burned out.

In view of the above problems, EXSENSE Electronics introduces a NTC thermistor with a base, which has the advantages of structural stability, production and use is not easy to damage, high production pass rate and low cost, and can effectively improve electrical performance. This NTC thermistor with a base includes an NTC thermistor chip, a glass head, two electrode leads and a base. The thermistor chip is encapsulated with glass, and one end of the two electrode leads is connected to the electrodes at both ends of the thermistor chip, the other end come through the bottom of the glass head. The bottom of the glass head is connected to a fixed base with two lead grooves and two electrode leads through two lead grooves.

Compared to existing technology, this thermistor uses the base to protect the connection between the electrode leads and the glass head, reducing the effect of external forces on that area. The two lead grooves of the base are separately for two electrode leads to pass through, which can limit the position of the two electrode leads and prevent short circuits of the two electrode leads due to too small spacing or contact with each other. This NTC thermistor effectively solves the problems of product break and damage cause by manual operation, testing, assembly process, while effectively solving the product leads prone to short circuit, greatly improve the safety factor of product use, can effectively meet the great reliable requirements for the electrical performance of the product, improve the service life of the product.