IGBT (Insulated Gate Bipolar Transistor), a composite fully controlled voltage-driven power semiconductor device made up of BJT (Bipolar Junction Transistor) and MOS (Metal Oxide Semiconductor). It has the advantages of high input impedance of MOSFET and low conduction voltage drop of GTR. GTR has low saturation voltage and large carrier density, but the driving current is higher; MOSFET has small driving power, fast switching speed, but the conduction voltage drop is large, carrier density is small; IGBT is combines the advantages of the above two devices due to its low driving power and low saturation voltage, which is very suitable for conversion system with DC voltage of 600V or above, such as AC motor, frequency converter, switching power supply, lighting circuit, traction drive, etc..

IGBT module is a modular semiconductor product made by IGBT and FWD through a specific circuit bridge package. IGBT module is energy saving, easy installation and maintenance, stable heat dissipation, etc., the encapsulated IGBT module is directly used in frequency converter, Uninterrupted Power Supply (UPS) and other equipment. With the advance of energy conservation and environmental protection, modular products will be more and more common in the market; IGBT is the core device of energy transformation and transmission, commonly known as the "CPU" of power electronic devices. As a national strategic emerging industry, IGBT is widely used in rail transit, smart grid, aerospace, electric vehicles and new energy equipment and other fields of application.

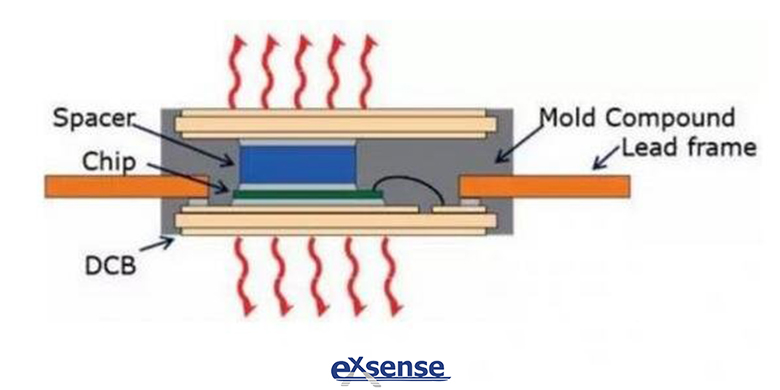

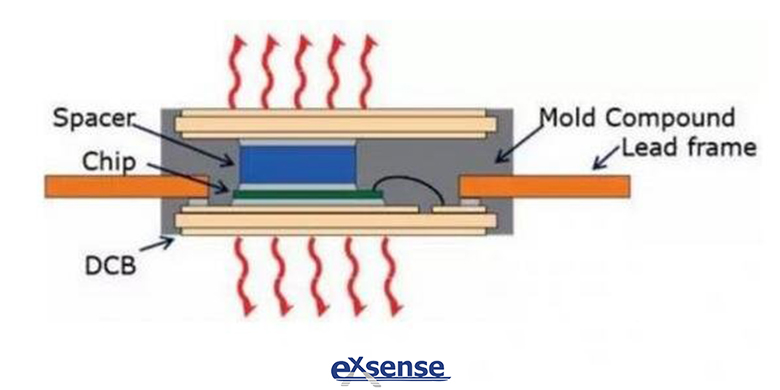

The use of IGBT for Dual-sided Cooling Technology (DSC), mainly to solve the problem of vehicle-mounted inverter power density in new energy vehicles (pure electric and hybrid power). As a dual-sided cooling module, IGBT first needs to ensure the mechanical consistency of its plastic sealing material under different working temperatures. As shown in the figure below, compared with the existing IGBT module, the DCB on the upper layer of the chip constitutes the second heat dissipation channel to improve the heat dissipation effect of the module.

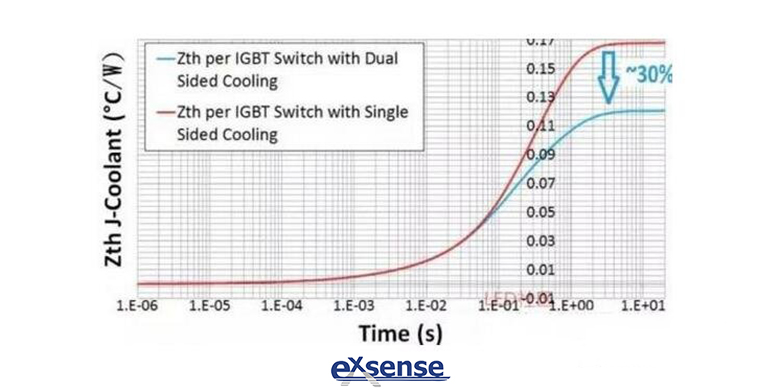

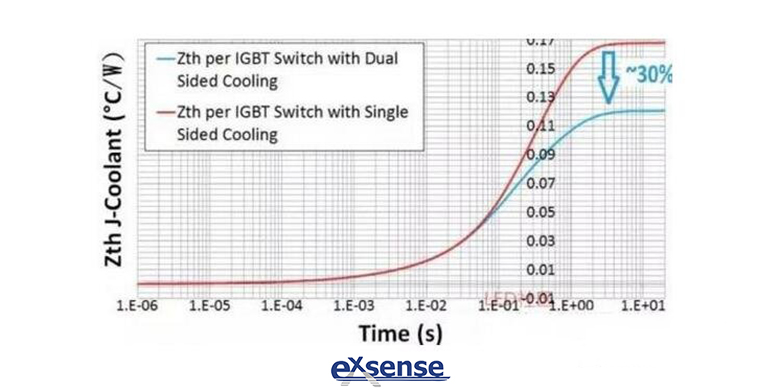

Due to the removal of the copper baseplate in the traditional design, the heat capacity of the module is significantly reduced, and its thermal coupling performance is greatly improved. Basically, the chip near the heat source has a higher temperature. At the same time, the new DSC module is accompanied by a significant reduction in parasitic inductance and encapsulated resistance. In addition, the module also integrates current and temperature sensor to facilitate the detection of chip current and temperature, which is not particularly different from conventional chip. The experiment as below shows that the output power can be increased by more than 30% after the dual-sided cooling is adopted under the same conditions.

NTC thermistor chip for IGBT produced by EXSENSE Electronics Technology Co., Ltd., using of advanced semiconductor process technology, combining with independent intellectual property rights, to ensure high stability and great reliability of continuous production of thermistor chips and manufacture higher precision NTC thermistor chips.