The resistance value of NTC thermistor chip decreases with the increase of temperature, so various electronic components made of thermistor chip are widely used in optical communication, household appliances, new energy automobile, consumer electronics, industrial production, etc. With the development trend of chip type and miniaturization of thermistor, NTC thermistor chip develops rapidly. At present, the development speed of NTC thermistor chip has far exceeded the traditional NTC thermistor. Therefore, the major manufacturers for the performance requirements of thermistor chip are becoming higher and higher, the preparation of a high-performance NTC thermistor chip has become the target of each manufacturer.

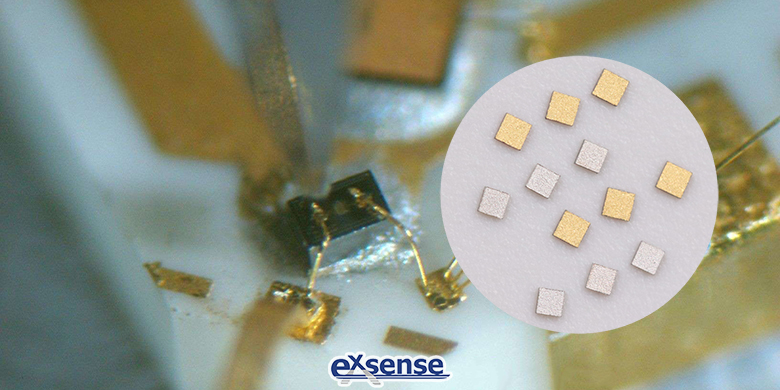

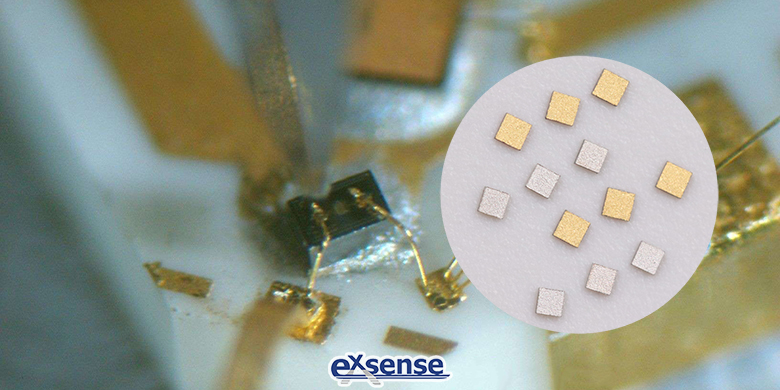

EXSENSE Electronics introduce a high-performance NTC thermistor chip, its preparation process is simple, process requirements are not complex, the performance of thermistor chip produced through this preparation method is great, the precision is high and the size is small. The specific preparation steps are as follows:

First, Mn-Ni-o binary, Mn-Co-Ni-O ternary and Mn-Co-Ni-O quaternary NTC powders are prepared by solid phase reaction synthesis method with analytical reagent as raw material;

Second, the raw materials are weighed in proportion, and anhydrous ethanol is used as dispersant. After two hours of ball milling, the materials are dried and then ground and screened;

Third, n the cold isostatic pressing machine for cold isostatic pressure, the process requirements is 280MPa, holding pressure for 8min;

Fourth, after isostatic pressing, the ceramic body is discharge of glue, and the process requirement is heat preservation at 550℃ for 80min;

Fifth, the ceramic body after the discharge of glue is put into the sintering furnace for sintering, and the process requirement is heat preservation at 1000℃ for 150min;

Sixth, the sintered ceramic body is sliced and the metal electrode is printed by screen printing;

Seventh, the ceramic substrate is put into the high temperature sintering furnace for high temperature sintering and infiltration, and the process requirement is heat preservation 550℃ for 30min;

Eighth, dicing ceramic substrate to get NTC thermistor chip, testing, packaging, storage.

The high-precision NTC thermistor chip produced by ESSENSE Electronics Technology Co., Ltd. has good performance, fast response, small size, which can be used for temperature monitoring and temperature controlling in the temperature range of -40~200℃.