Guardian of BMS: Close Collaboration Between NTC Thermistor and CCS Cell Contacting System

With the rapid development of new energy technology, the design and manufacture of BMS (Battery Management System) are also changing with each passing day. While pursuing diversified requirements such as high integration density, long service life, low cost, etc., BMS puts forward more stringent requirements for the safety and reliability of its own temperature monitoring. Among them, CCS (Cell Contacting System) and NTC thermistor play key roles in achieving this goal for BMS.

The traditional BMS temperature monitoring solution selects the wiring harness, which has the complex process, high cost and a large proportion of assembly space. In order to solve the above problems and make the design of BMS more intelligent, greenization and integration, CCS solution for real-time temperature control and temperature measurement through NTC thermistor is rapidly penetrating, and major new energy manufacturers are continuing to advance. NTC thermistor and CCS work closely together in the BMS to ensure its safe and stable operation. CCS provides a reliable mounting platform for thermistors, making temperature monitoring more accurate and smooth. At the same time, the real-time temperature data fed back by NTC helps to optimize the thermal management of the BMS, further improving the performance and life of the BMS.

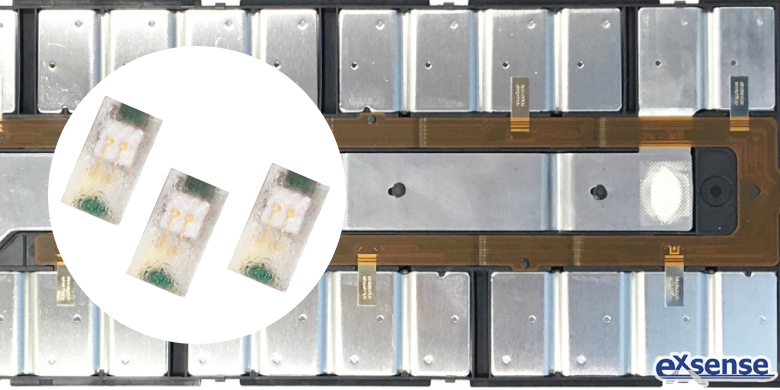

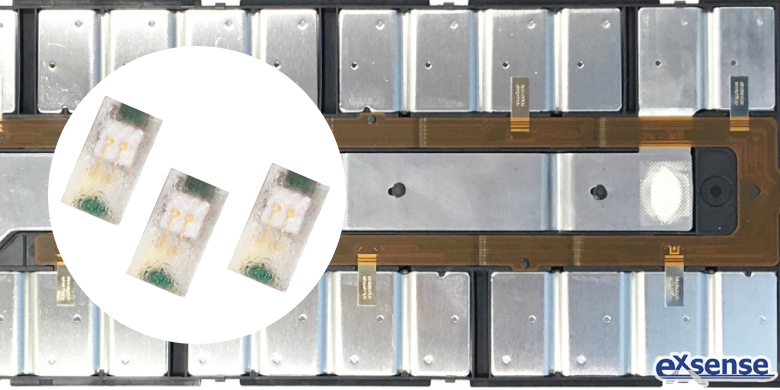

In the existing CCS scheme, NTC thermistor and other components are usually set on the FPC in the CCS to make the overall structure more compact and improve the integration level. Compared with traditional wiring harness, in order to reduce the error of temperature monitoring better, FPC generally uses SMD type NTC thermistor, which can be placed closer to the battery cell and improve the temperature control accuracy of CCS to BMS. In addition, while traditional wiring harnesses need to be electrically conducted through terminals, FPC and NTC use surface mount technology, which simplifies the production process and reduces production costs.

In order to cooperate with the upgrading of BMS manufacturers in recent years, EXSENSE Electronics Technology Co., Ltd. has launched a new self-developed CB series SMD type NTC thermistor, which has excellent bending ability compared with the traditional SMD thermistor, complements FPC in CCS, which can adapt to complex assembly environments. In addition, its accuracy can reach ±0.1℃, which helps CCS to carry out high-accuracy real-time temperature monitoring and control. In addition, CB series SMD type NTC thermistor responds quickly, which helps to detect abnormal temperature in time and prevent thermal runaway when BMS is working. CB series SMD type NTC thermistor and CCS complement each other, which not only improves the overall performance of BMS, but also reduces its manufacturing cost and helps the sustainable development of BMS industry.