In recent years, the new energy vehicle industry has continued to develop, people have increasingly high requirements for the endurance mileage, charging speed and performance of new energy battery. Compared with traditional semiconductor modules, SiC silicon carbide module has improved the energy conversion efficiency of BMS battery management systems due to its advantages of high switching frequency, low conduction loss, high withstand voltage, etc. The internal temperature monitoring and control of the BMS has attracted widespread attention, and the temperature protection through the NTC bare chip can effectively avoid the occurrence of adverse situations caused by poor heat dissipation.

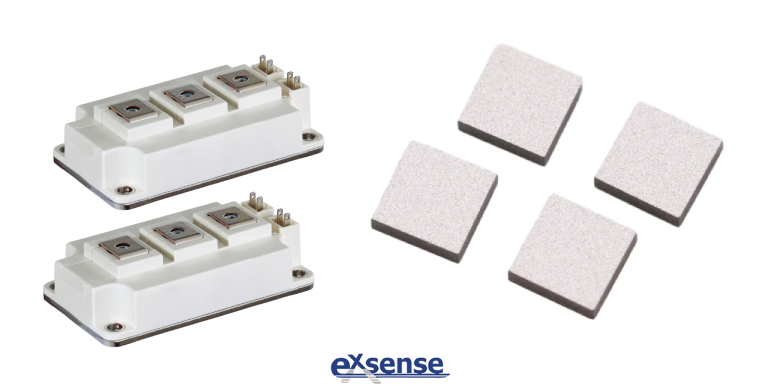

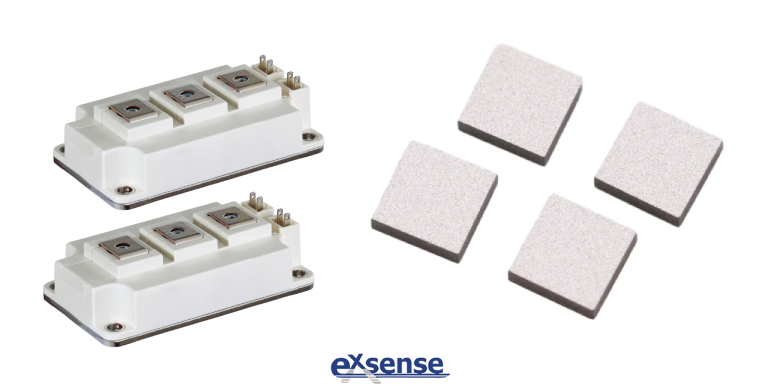

Compared with thermocouples and other components, NTC bare chip has higher sensitivity, which can respond more quickly during the temperature measurement process of SiC silicon carbide module, it provides a guarantee for the safe operation of module. The bare chip is soldered to the substrate of the silicon carbide module and the temperature measurement is using bonding process. When the temperature of the module changes, the resistance value of the NTC chip will change accordingly, and it will be converted into the real-time temperature value of the module through the algorithm, which can be synchronously fed back to the BMS control module and transmit the information to the control panel, so that the driver can observe the working condition of BMS in real time.

The traditional NTC bare chip for silicon carbide module is prone to metal ion migration due to high-temperature operation during the bonding process, resulting in the reduction of NTC metal electrode area, which increases the resistance value of the bare chip, resulting in the deterioration of electrical properties and also affects its soldering performance. In order to improve the above technical problems, EXSENSE Electronics Technology Co., Ltd. has developed a solderable NTC bare chip suitable for wire bonding, which adds a barrier layer between the metal electrode and the semiconductor ceramic, which can prevent the electrode migration caused by high-temperature soldering to change the resistance value of the NTC chip. In order to assist major silicon carbide module manufacturers in optimizing their solutions, this bare chip is also suitable for a variety of chip bonding processes such as silver sintering, reflow soldering, and silver adhesive, etc. In addition, the solderable NTC bare chip also has the following characteristics:

First, high reliability, so that it has better electrical performance;

Second, small size, suitable for installation in compact modules such as silicon carbide to improve the degree of integration;

Third, great soldering resistance, can withstand high-temperature and long-term reflow soldering;

Fourth, high sensitivity, the fast response to temperature can convey data in time to ensure the stable operation of the silicon carbide module.

Solderable NTC bare chip integrated in SiC silicon carbide module provides real-time temperature monitoring for efficient thermal protection to ensure excellent reliability of SiC. At the same time, its addition also reduces the overall design and development cost of the module, so the solderable NTC bare chip suitable for wire bonding plays an indispensable role in the SiC silicon carbide module.