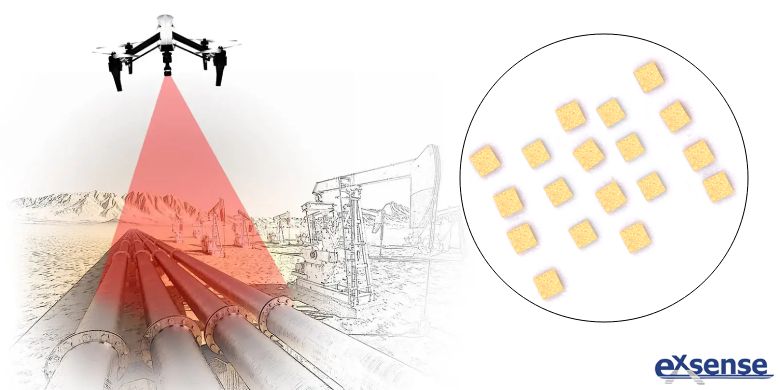

Due to the improvement of industrial automation and safety standards, gas leak detection is more and more widely used in industrial safety, environmental monitoring and other fields. However, traditional gas leak detection sensors are prone to a decrease in monitoring sensitivity and data accuracy when the ambient temperature changes too quickly. In order to improve this technical problem, gas leak detection sensor manufacturers will choose to insert NTC bare chip to make the gas leak detection sensor work within a safe temperature range by using its temperature-sensitive characteristics.

The resistance value of the NTC chip is negatively proportional to the temperature, which prevents the gas leak detection sensor from being affected by temperature changes while it is operating. Specifically:

First, when the ambient temperature interferes with the monitoring work of the gas leakage detection sensor, it will lead to errors in the measurement results. The temperature monitoring of the sensor through the NTC bare chip can detect the temperature anomaly in time and provide a basis for subsequent temperature control.

Second, since the center wavelength of the laser inside the gas leak detection sensor is easy to drift with temperature changes, setting NTC can correct the deviation caused by temperature changes in real time to ensure that the sensor can maintain stable measurement at different ambient temperatures.

Third, using the temperature signal monitored by the bare chip, the control module of the gas leakage detection sensor can adjust the heating power of the heating and insulation module, so that the sensor can work at a constant temperature and improve its measurement accuracy and stability.

In summary, when the gas leak detection sensor starts to work, the NTC chip will monitor the ambient temperature in real time and transmit the obtained temperature information to the control module. The control module reads and parses the temperature information and compares it with a preset temperature threshold. As soon as the ambient temperature changes beyond the preset range, the control module immediately takes protective measures. For example, when the ambient temperature is too low, the control module may start the heating and holding module to balance the temperature by heating; Conversely, if the ambient temperature is too high, the control module adjusts the power of the heating and holding module to prevent the sensor from overheating, thus achieving precise control of the sensor temperature.

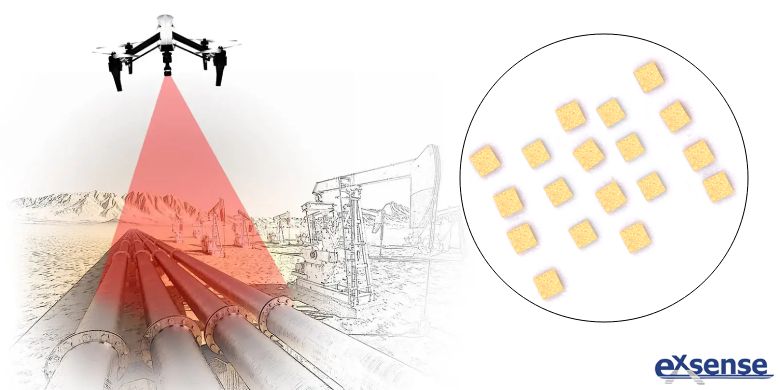

Therefore, in order to ensure the working stability of the gas leak detection sensor, the temperature measurement accuracy of the NTC bare chip is relatively higher. EXSENSE Electronics Technology Co., Ltd. recommends the use of DT series gold electrode NTC bare chip, which accuracy can reach ±0.3%, to achieve accurate monitoring of the working temperature of gas leak detection sensor. In addition, the small size (0.32mm×0.32mm) of the gold electrode NTC bare chip can meet the needs of the development of gas leak detection sensor in the direction of high integration, and promote the gas detection industry to move towards miniaturization.