Manufacturing method of high-precision and high-reliability NTC thermistor Chips-3

Based on the steps of <Manufacturing Method of High-precision, Highly-reliability NTC Thermistor Chips-2>, let’s illustrate it with the following specific examples:

1. Using analytical balance to weigh Mn3O4 405.2g, NiO 457.04g, Fe2O3 599.30g, Ai2O3 39.42g accurately, mix and ball billing the above materials for 20 hours, crush and calcine at 950 ℃ for 2 hours after drying, then ball billing 20 hours again, get the traditional coarse granular powder (the particle size of the powder is 1-5μm).

2. According to the same metal ion molar ratio, make nickel nitrate, manganese nitrate, iron nitrate and aluminum nitrate into 0.7mol/L aqueous solution, use ammonium hydroxide to adjust the PH=7, ultrasonic spray drying in the stirring state, calcine at 450℃ for 4 hours, to obtain nanoscale powder.

3. Weight 375g nanoscale powder to add into the coarse granular powder, stir while add the deionized water to make slurry. Wherein, the additive amount of water accounts for 25wt% of the mixed powder (the above nanoscale powder + coarse granular powder).

4. Pressure filtrating the slurry in the pressure filtrating molding, increase pressure is10mpa, pressure maintaining 2min, made into a cylinder of diameter 52mm, high 16mm, baking 1h at 100 ℃ then put into the cold isostatic press to suppress 2mins at 300mpa .

5. In the microwave oven, make the temperature from room temperature warming to 1050 ℃ with the speed of 10℃/min, heat preservation 30mins, then cooling to 500 ℃with speed 2℃/min, cooled to room temperature naturally, to obtain ceramic spindle.

6. Use a wafering machine to cut the ceramic spindle into a wafer of thickness 0.3mm, diameter 52mm; electrode printing on the wafer, sintering at 800 ℃ then do the heat treatment: heat the prepared wafers up to 800 ℃ with speed 5℃/min, and heat preservation 24 hours on this basis, then cool to room temperature with speed 2 ℃/min, argon gas is used as a protective atmosphere during the entire heat treatment process.

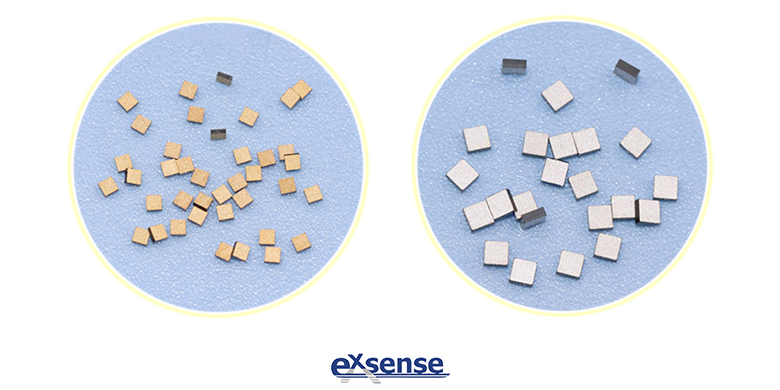

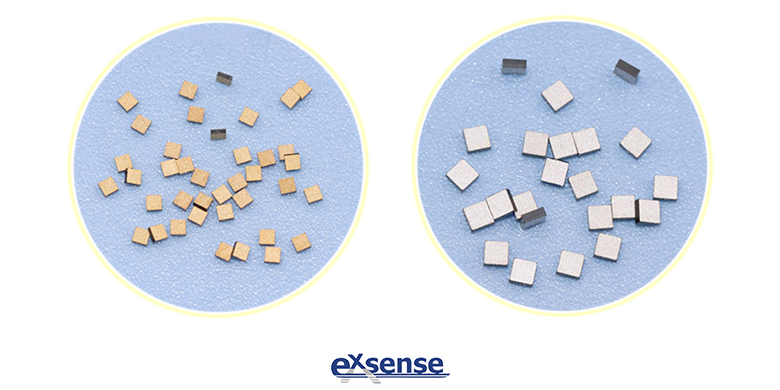

7. Use the cutting machine to cut into NTC thermistor chip of 0.8*0.8mm.

60 pieces NTC thermistor chip obtained by this method was randomly selected to measure its resistance value at 25 ℃. Compared with the NTC thermistor chip prepared by the traditional method, the pass rate of the NTC thermistor chip which resistance value within 10kω±1% was 95.7% in the new process, and the pass rate of the resistance value within ±1% was 75.3% in traditional method. That is, the pass rate of resistance has a large increase relatively.

Then, the 60 pieces NTC thermistor chips are divided into two parts, after welding and sealing, half of them are aging 1000 hours in the oven at 110 ℃, the other half are doing the thermal shock 1,000 times in the tank at -30~100℃, to measure the resistance changes before and after the test respectively. The change rates of new process are 0.36% and 0.344%, while the values of the traditional methods are 0.92% and 1.09%. Thus, the use of new technology can make the precision and reliability of resistance values of NTC thermistor chip increase greatly.