NTC chips are widely used in various circuits of temperature detection, temperature compensation, temperature control, which play a central role in converting temperature variables into required electronic signals. Existing NTC chips generally include NTC thermal ceramic substrates and metal electrodes on both surfaces, and metal electrodes are usually silver electrodes. The preparation process of the existing NTC chip is: materials preparation of NTC thermal ceramic powder - ball milling - isostatic press moulding - ceramic ingots sintering - sling - silver slurry printing - drying - burnished silver - cutting-up.

However, the use of silver electrodes and the use of screen printing method have the following problems:

(1) Silver slurry in the process of screen printing and drying is vulnerable to pollution, and the resulting silver electrode is also easy to oxidize, yellowing and blackening, resulting in poor stability and reliability of the product;

(2) The pre-preparation of silver slurry, late-drying silver slurry and sintering of silver electrodes are more cumbersome;

The thickness of the silver electrode layer produced by screen printing is larger, and the surface of thermal ceramic substrate is covered unevenly, which is easy to peeling and produce burrs in the process of cutting-up, the loss of silver slurry is more;

(4) When the silver layer is sintered at high temperature, its crystal form will recrystallize, thus changing the performance, resulting in the decline of the electrical performance of the product;

(5) The gas emitted during the process of burning silver at high temperature will cause pollution to the environment.

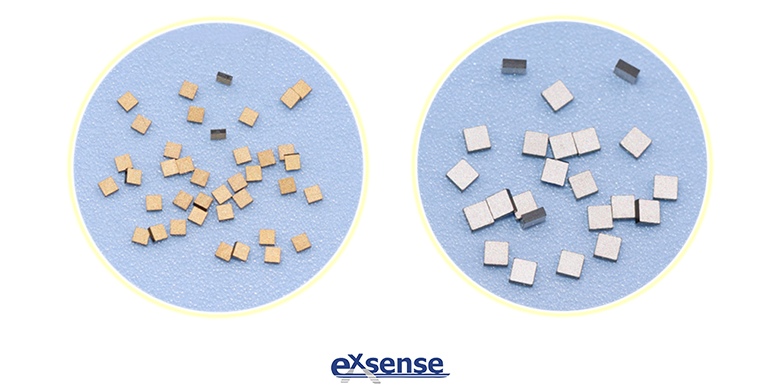

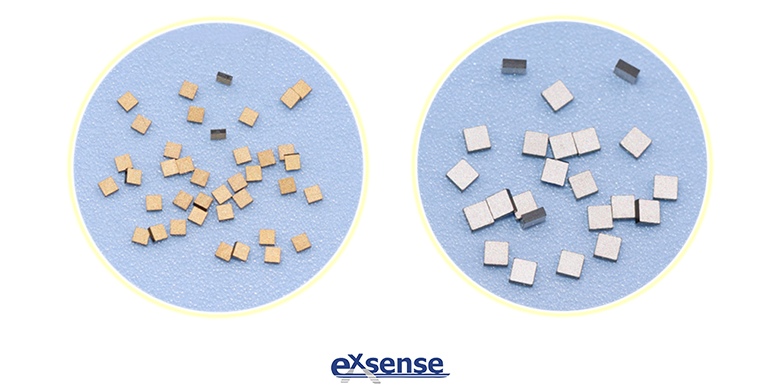

In view of the above problems, EXSENSE Electronics introduce a high-precision high-reliability Ti-Cu-Au composite electrode NTC chip, which has the advantages of good stability, great reliability, non easy to aging, and resistance to cold and heat shock. This Ti-Cu-Au composite electrode NTC chip includes NTC thermal ceramic substrate and two composite electrodes placed on its two surfaces. The composite electrodes are made of titanium layer, copper layer and gold layer, which are laminated from the inside out on the surface of the NTC thermal ceramic substrate.

Ti-Cu-Au composite electrode NTC chip, its titanium layer (Ti) acts as transition layer (thickness is 0.01 to 1 micron), mainly plays a transitional role, which can be well combined with NTC thermal ceramic substrate, and play a certain blocking role; The copper layer (Cu) acts as barrier layer (thickness is 0.01 to 22 micron), it is used to prevent external damage to the transition layer and has the function of welding; Gold layer (Au) is not only the welding layer (thickness is 0.01~1 micron), but also the protective layer with high stability, which can prevent oxidation, corrosion, destruction and high temperature.

The titanium layer, copper layer and gold layer are layered from the inside out to make a composite electrode on the surface of the NTC thermal ceramic substrate by vacuum sputtering. Compared with screen printing, the vacuum sputtering method is used to prepare the metal layers, with the following beneficial effects:

(1) The sputtering process is carried out in the vacuum sputter coating equipment, which will not pollute the environment, and has high cleanliness, to ensure that the surface cleaning is not be polluted twice;

(2) Eliminate the complicated preparation of silver electrode silk printing method, after finishing sputtering in vacuum sputtering equipment, it can be put into use;

(3) The thickness of the metal layer obtained by sputtering can reach less than 1% of the thickness of the silk-printed silver electrode layer, which saves material, and the composite electrode and the NTC thermal ceramic substrate are tightly bonded by the sputtering process, which is not easy to peeling and produce burrs in the process of cutting-up;

(4) Sputtering process is easy to be controlled, the area of metal layers obtained by vacuum sputtering is large and they’re evenly covered and combined with NTC thermal ceramic substrate, the surface is very dense, which can effectively prevent external erosion, so that the product truly achieve high precision, great reliability, and can eliminate the performance change caused by high temperature sintering of silver layer after screen printing;

(5) There is no process of drying and sintering electrode layer, which can avoid air pollution caused by emission of harmful gas.

Ti-Cu-Au composite electrode NTC chip, compared with the traditional NTC chip, its stability, temperature resistance, corrosion resistance, anti-destructive has been effectively improved, its reliability and accuracy has been significantly improved.