NTC chip is based on transitional metallic oxides as the main raw material, manufactured by advanced ceramic technology. The resistance range of NTC chip at room temperature is 100~ 1000KΩ, the temperature coefficient is -2% to -6.5%, using these characteristics, NTC chip can be widely used in temperature monitoring, temperature compensation, temperature control, suppression of surge current and other occasions.

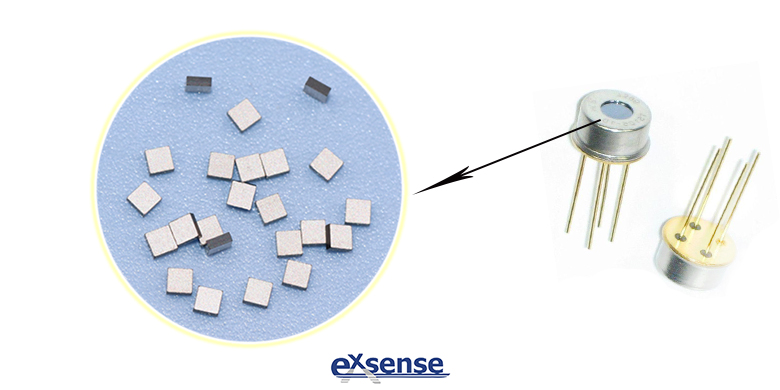

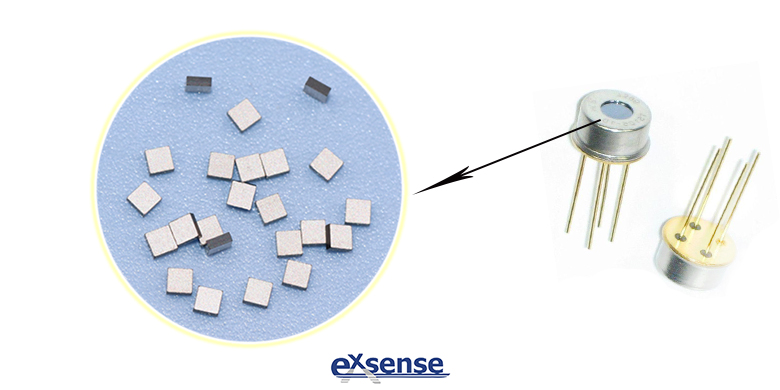

Infrared thermopile is one of the components that reflect the role of NTC chip in temperature monitoring. Thermopile is an infrared thermal pyroelectric sensor composed of thermocouple, which is widely used in infrared thermometer, thermal infrared imager, electric oven and so on. NTC chip plays an indispensable role in temperature monitoring of infrared thermopile, and the chip are basically processed in a bonding process. In the existing technology, most manufacturers are selected silver electrode NTC chip and aluminum wire for bonding, but its disadvantage is that the tension is weak. EXSENSE Electronics recommend to use gold electrode NTC chip and aluminum wire for bonding, because the combination between gold electrode NTC chip and aluminum wire can have a better tension.

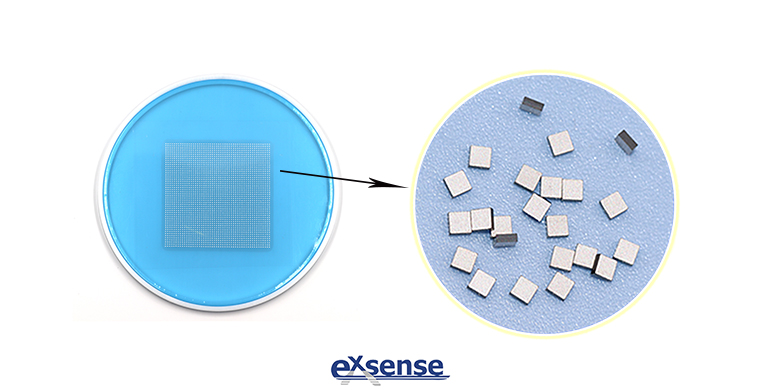

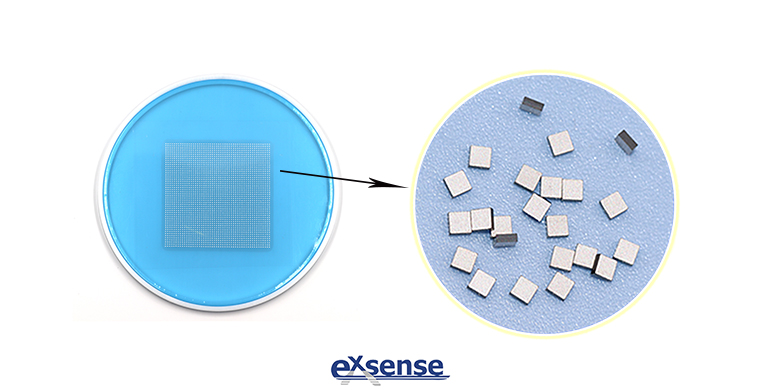

Customers’ parameter requirements for NTC chips vary depending on the industry in which they are used, and so will the packaging. To this end, EXSENSE electronics also provide a variety of packaging methods, such as vacuum bulk, glass bottles, blue plastic film, etc., to provide customers with more convenient and better service. Among them, for the infrared thermopile industry and the IGBT industry, EXSENSE Electronics recommended the blue plastic film packaging. This packaging method is suitable for the production of IGBT, infrared thermopile NTC/COB technology.

In the past, most manufacturers shipped chips in anti-static bags. After receiving the NTC chip, customer needs to place the chip on the film for mechanical operation, and then proceed to the next production process. This will lengthen production time and reduce production efficiency. In view of the above problems, now EXSENSE electronics are use machine to make the blue plastic film packaging (The size of blue plastic film can be customized according to customer requirements) after the NTC chip is finished, then put them into a special plastic box for packaging. After receiving, the customer can directly operate on the machine to improve production efficiency and save production time.

The gold electrode NTC chip produced by EXSENSE Electronics Technology Co., Ltd., with characteristics of high precision, good consistency, fast response speed and so on, plays an important role in temperature monitoring of the infrared thermopile.