With the rapid development of electronic equipment, NTC chip is more and more widely used in temperature monitoring, temperature compensation and temperature control. In the existing technology, manufacturing material of NTC chip is usually ceramic or polymer, the manufacturing process is generally: powder preparation - ingots sintering - slicing - electrodes printing - sintering- edge remove and chip selecting - Dicing. This type of NTC chip includes metal electrodes and ceramic body, metal electrode layer is located on the two surfaces of the ceramic body, the metal electrode completely covers the two surfaces of the ceramic body. In the subsequent processing, according to different needs, NTC chip is usually installed and fixed by using welding, bonding and other method. When NTC chip is fixed by welding, due to the metal electrode surface of the chip is on the same level with the surface of ceramic body, it is easy to cause short circuit at the top and bottom of the chip. When NTC chip is fixed by bonding, the silver paste is easy to cross from one side of the metal electrode to the other side of the metal electrode along the side of the ceramic body, resulting in short circuit. The short circuit problem of NTC chip will greatly increase the production cost and hinder the production.

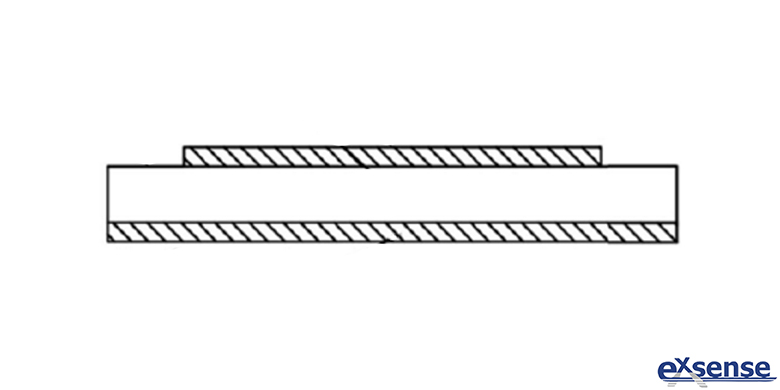

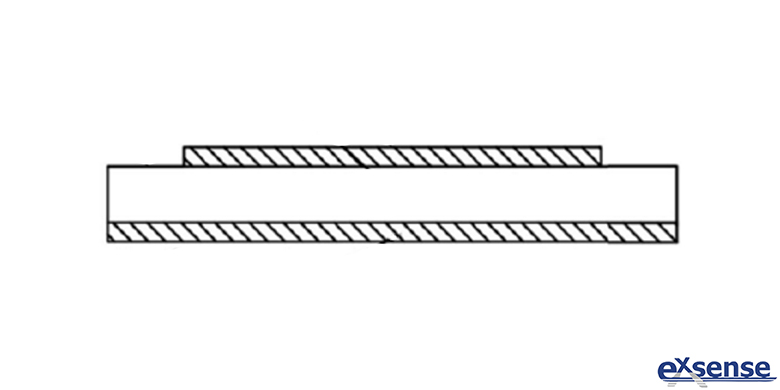

In order to overcome the shortcomings of the existing technology, EXSENSE Electronics introduces a short-circuit-proof NTC chip, which includes the thermal substrate, the first metal electrode layer and the second metal electrode layer. One surface of the thermal substrate includes the electrode area and the insulation area, the insulation area is surrounded by the outer part of the electrode area. The first metal electrode layer is located on the surface of the electrode area, the second metal electrode layer is located on the other surface opposite the thermal substrate to the electrode area, and the thickness of the first metal electrode layer and the second metal electrode layer is ≥5μm.

The preparation method of this short-circuit-proof NTC chip is as follows:

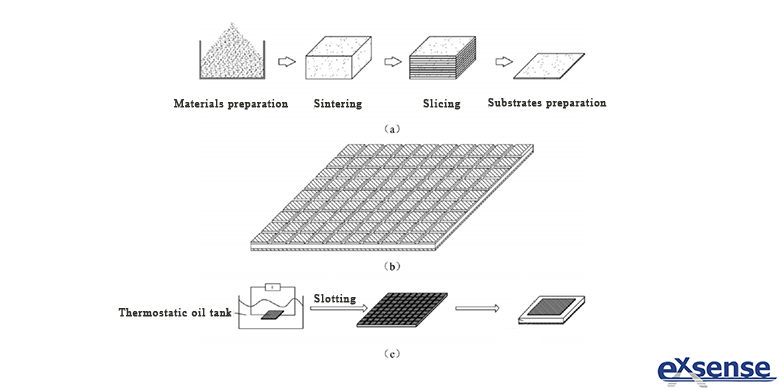

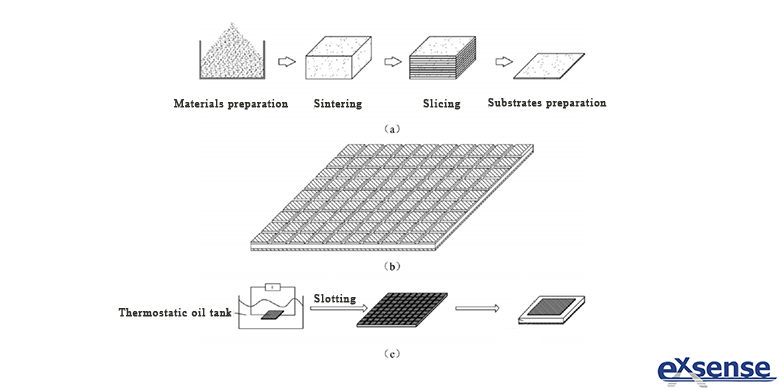

1, The preparation of thermal substrate: through the powder preparation - ball milling - sintering - slicing - cleaning, to obtain the thermal substrate.

According to the material formula, various metal oxides (manganese, cobalt, iron, nickel, copper, zinc) are formulated in accordance with the corresponding proportion of the mixed material; Then the material is poured into the mold, after preliminary hand press molding, under ultra-high pressure to continue molding, to obtain ingots; The ingots are added to the alumina bowl which has been prepared with alumina sand, the spindle is then sintered with alumina sand, to get sintered ingots; The ingots fixed on the special fixture of inner cutting machine, adjust the parameters for cutting, then ultrasonic clean with pure water and dry, to obtain a thermal substrate.

2, Metal slurry is printed on both sides of thermal substrate and sintered into electrodes, alternating grooves are formed on on one side of the the electrodes of the thermal substrate.

3, Along the grooves of the thermal substrate for cutting, to get short-circuit proof NTC chip.

Cut slotting on one side of the thermal substrate (the slotting position is calculated according to the test results of the resistance tester), after the metal electrode in the groove is removed, the NTC chip is cut along the groove to obtain a short-circuit-proof NTC chip.

The short-circuit-proof NTC chip, by forming an insulation area on the surface of the thermal substrate, without increasing the cost of device fabrication, greatly reduces the possibility of short-circuiting of the chip, thereby reducing production costs and improving production quality. EXSENSE Electronics Technology Co., Ltd. adopts advanced semiconductor process, combined with independent intellectual property rights of NTC chip materials and processing technology, through high-precision material processing, slicing, packaging and testing equipment imported from Japan, Taiwan, Germany, to achieve the high-precision batch manufacturing of NTC chips.