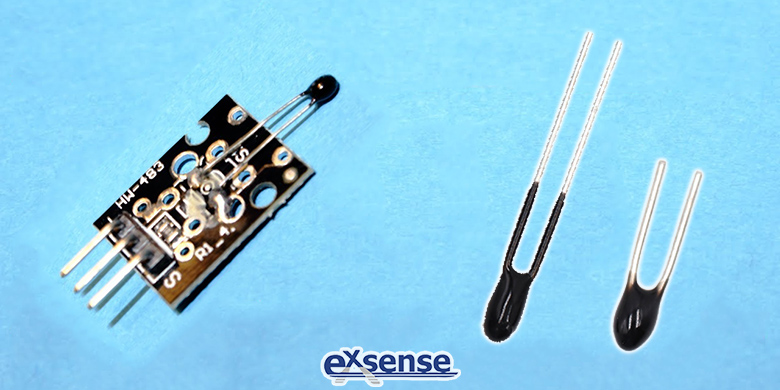

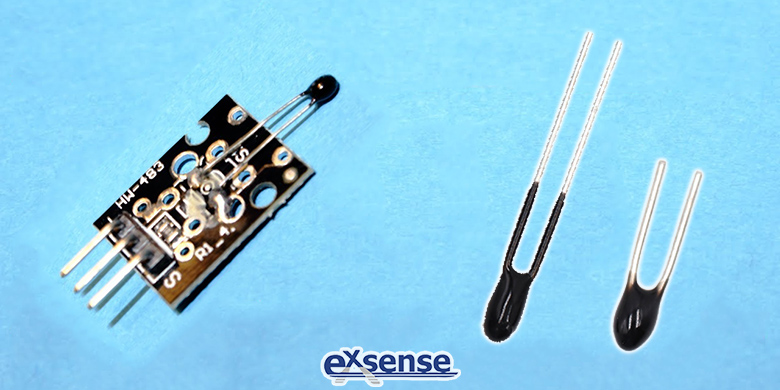

NTC thermistor produced by EXSENSE Electronics Technology Co., Ltd. has the advantages of high sensitivity, small fluctuation of temperature characteristic, fast response to temperature change, etc. It is widely used in household appliances, medical instruments, temperature measurement of automobile, fire alarm and other fields. In the existing technology, two or more metal oxides such as manganese, copper, silicon, cobalt, iron, nickel and zinc are usually used as NTC thermistor materials. Under the condition of repeated current flow, NTC thermistor made by existing technology are prone to current breakdown or aging drift, thus reducing its service life.

In order to solve the above technical problems, EXSENSE Electronics introduces a NTC thermistor, which has low resistance drift rate, good effect of resistance to current impact and long service life. The specific preparation method is as follows:

First, mix the NTC thermistor material according to the proportion of ingredients and pour into the ball mill for ball grinding for 40 hours, and then the material is sintered at 125℃, sintering time is 12 hours, so as to produce dry raw materials;

Second, weigh and take 600g of dry material, add 24g phthalic acid dibutyl ester and 9g white latex, mix evenly to get thermistor paste;

Third, through the processes of first stamping, the first drying, the second stamping, the second drying, the third stamping, sintering, the fourth stamping making thermistor paste into thin slice, and the thin slice are sintered, and then the sintered slice is polished on both sides, to obtain blank piece.

Fourth, the blank piece is cut into square and put into the oven to dry at 60℃ for 10mins;

Fifth, sintering the blank piece under the control of the PID controller at 60℃ for 12 hours, secondary sintering after cooling to room temperature, temperature control with the PID controller, respectively sintering at 60℃ for 1 hour, 1 hour sintered at 70℃, 1 hour sintering at 80℃, 1 hour sintering at 90℃, 1 hour sintering at 100℃, 1 hour sintered at 110℃, 6 hour sintered at 126℃;

Sixth, use grinding machine to polish the sintered blank piece on both sides to get the blank piece with smooth surface;

Seventh, the blank piece is arranged in the refractory box and sintered, sintering temperature is 1290℃;

Eighth, apply diluted silver paste on both sides of the blank piece, in which the weight ratio of silver paste and silver paste thinner is 100:5;

Ninth, the blank piece coated with silver paste is sintered at 125℃ for 10-15min until it is dried and put into the refractory box, sintered at 650℃ with PID controller.

Tenth, cut the chip into small pieces according to the requirements of the resistance value to get the NTC chip, and weld the leads and encapsulate the epoxy resin to get the NTC thermistor with low resistance drift rate.