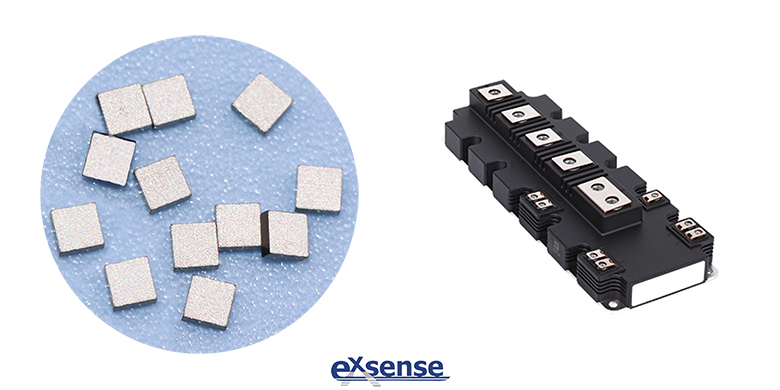

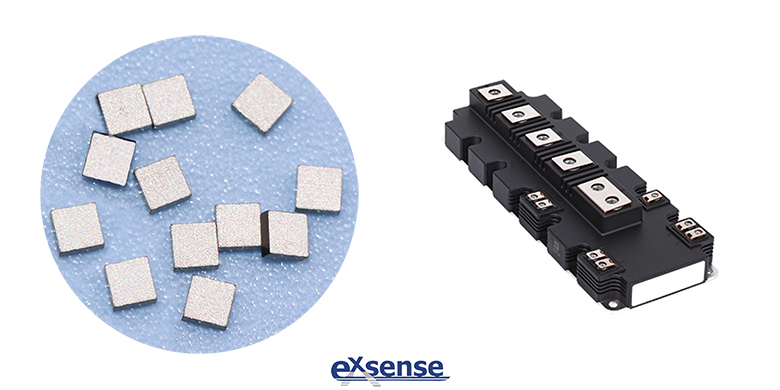

As a national strategic emerging industry, IGBT modules are widely used in the fields of rail transit, smart power grid, industrial energy saving, electric vehicles and new energy equipment, which are known as the pearl on the crown of semiconductor. IGBT thermistor chip produced by EXSENSE Electronics Technology Co., Ltd. has the characteristics of high precision, fast reaction, great reliability, etc, which plays the role of temperature monitoring and temperature controlling in IGBT module.

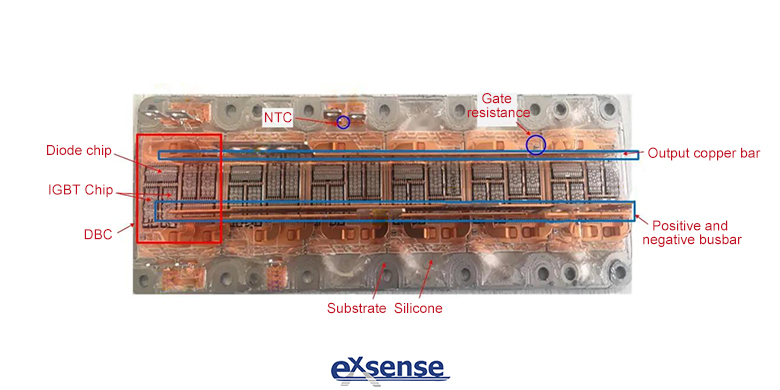

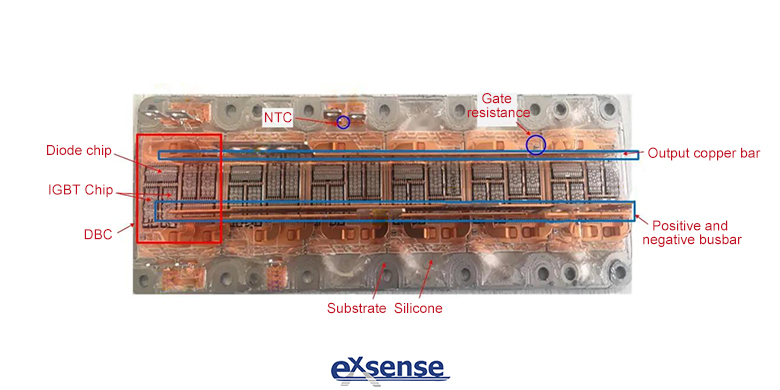

There are many series of IGBT modules, each of which contains slightly different components. Today, EXSENSE Electronics takes the IGBT module in the figure above as an example to deconstruct its internal structure. This IGBT module contains two IGBTs inside, which is often referred to as the half-bridge module. The IGBT module consists of four components, namely, heat dissipation substrate, NTC thermistor chip, DBC (Direct Bond Copper) substrate and silicon chip (including IGBT chip and Diode chip). The rest is mainly the solder layer and the interconnect wire, which are used to connect IGBT chip, Diode chip, power terminal, control terminal and DBC. Next, let's talk more about:

Heat dissipation substrate:

At the bottom of the IGBT module is the heat dissipation substrate, the main purpose of which is to quickly transfer the heat generated by the IGBT switching process. Due to the good effect of heat conduction of copper, the substrate is usually made of copper, and the thickness of the substrate is 3 to 8mm.

DBC substrate:

DBC substrate is a kind of ceramic surface metallization technology, a total of three layers, the middle is a ceramic insulation layer, upper and lower are copper-clad layers. DBC substrate is the copper layers clad on both sides of the insulating material, and then the current graphics is etched on the front. Because the back needs to be directly welded on the heat dissipation substrate, there is no need to etch. The main function of DBC needs to ensure the electrical insulation ability and good heat conduction between the silicon chip and the heat dissipation substrate, as well as to meet a certain current transmission capacity.

IGBT chip:

The IGBT gate pole and emitter pole are located at the top (front) of the IGBT chip, and the collector is located at the bottom (back) of the IGBT chip. The thickness of the chip is 200μm. When the IGBT is powered on, the current flows from the bottom to the top, so the IGBT with this structure can also be called vertical device.

NTC Chip:

Two NTC thermistor chips are welded on the module, which are used for temperature monitoring and over-temperature protection.

Bonding wire:

The interconnection of the upper copper layer of IGBT chips, Diode chips and DBC is generally realized by bonding wires. The commonly used bonding wires are aluminum wires and copper wires. Among them, the bonding process of aluminum wire is mature and the cost is low, but the electrical and thermodynamic properties of aluminum wire bonding are poor, and the expansion coefficient mismatch is large, which affects the service life of IGBT. Bonding process of copper wire has the advantages of excellent electrical and thermodynamic properties, great reliability, which is suitable for high power density, efficient heat dissipation modules.