With the adoption of wide band gap materials such as silicon carbide (SiC) and gallium nitride (GaN), the operating temperature of automotive grade IGBT continues to increase, and accurate monitoring of temperature becomes more important, and temperature control is one of the key factors for its effective operation. Typically, MOSFET in IGBT are equipped with internal temperature sensor such as body diode for real-time temperature monitoring. However, whether IGBT is using process technologies such as silver sintering, SMT or chip wire bonding, NTC thermistor is still a better choice because of its high sensitivity, high temperature resistance, and great consistency. Through the designer's reasonable design, the NTC thermistor can assist the IGBT module to correctly reduce its load, shutting down if its operating temperature is out of range (overheating/too high external temperature).

In addition to NTC thermistor, some manufacturers also use other components to monitor the real-time temperature of automotive grade IGBT. Such as semiconductor silicon PTC thermistor, which can well perform current control; Or platinum-based/niobium-based resistance temperature detectors (RTD) that can use lower resistance to achieve higher detection linearity. But the application of semiconductor silicon PTC thermistor means that IGBT needs to maintain a positive temperature coefficient (PTC), which increases the probability of IGBT thermal runaway. Therefore, compared with the semiconductor silicon PTC thermistor, NTC thermistor whose resistance value decreases with increasing temperature can better assist on-off of the automotive grade IGBT. In addition, compared with NTC thermistor, platinum-based/niobium-based RTD has higher cost and lower cost performance.

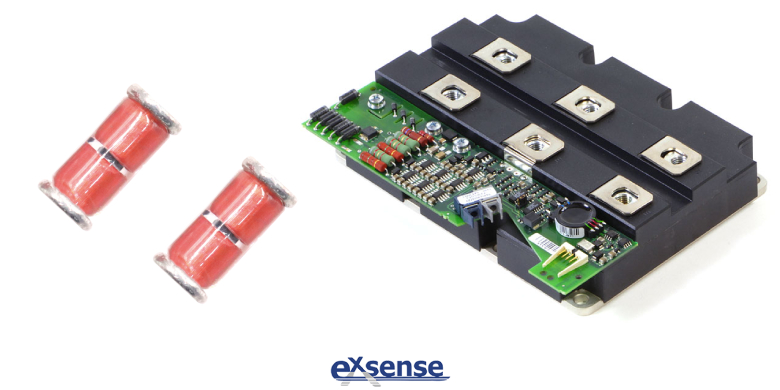

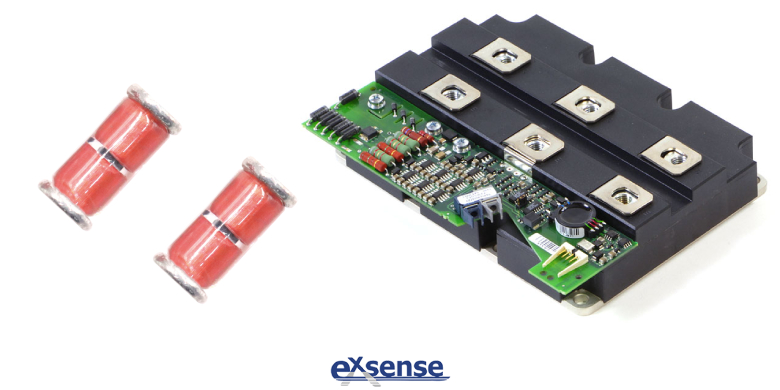

With automotive grade IGBT module carrying currents up to 300A and DC bus voltages up to 400V, real-time temperature monitoring is a key criterion for overload protection. The integration of NTC thermistors with automotive grade IGBT disables the IGBT gate driver when the IGBT operating temperature rises above the high temperature threshold, providing thermal shutdown and avoiding overheating of the IGBT module. In general, NTC thermistor placed on substrates within IGBT or MOSFET are mostly MELF glass encapsulated NTC thermistor, which is high temperature resistance (operating temperature can up to 250℃), high reliability; At the same time, its chip structure is easy to install, so it is in line with the IGBT module. In addition, in order to promote the sustainable development of SiC module and help IGBT manufacturers to simplify the process, a new weld-resistant chip type NTC thermistor is introduced by EXSENSE Electronics Technology Co., Ltd., the chip welding surface of NTC thermistor chip is suitable for high temperature welding, and the wire bonding surface is suitable for wiring process, which can better play the role of temperature monitoring in the automotive gauge IGBT module.