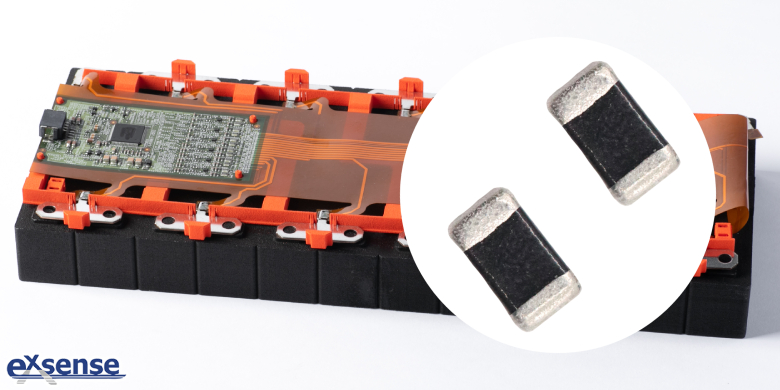

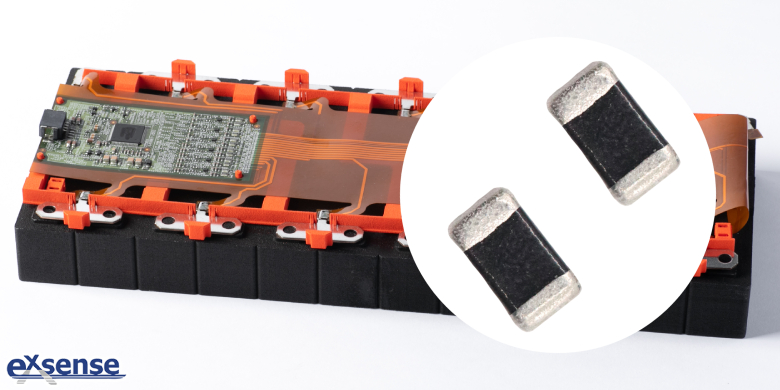

Thermal Runaway Prevention of Battery Module: Combination of NTC Thermistor and CCS

In recent years, people's awareness of environmental protection has gradually increased, which has led to an increase in global demand for renewable energy. As the energy storage devices, battery module has also risen rapidly in the development of the industry in the process of energy transition. The traditional NTC wiring harness solution is difficult to meet the current integration requirements of battery module due to the large space occupation and complex wiring. In this context, the CCS (Cell Contacting System) solution that uses NTC thermistors instead of wiring harnesses for temperature monitoring has come into being.

CCS is the key to connect multiple cells in the battery module, which not only ensures the reliable connection between the module cells, but also assists the battery management system for efficient management and monitoring. The use of NTC thermistor in CCS can realize real-time monitoring of cell temperature and provide a strong guarantee for the safe operation of battery module. CCS of battery module is the high integration of busbars, NTC thermistors, and FPC (Flexible Printed Circuit). Specifically, the NTC is welded on the FPC of CCS, which can accurately and real-time monitor the temperature change of the battery cell and provide immediate feedback to the battery management system to prevent damage to the battery module caused by abnormal temperature. Why does CCS have an advantage over traditional wiring harness solutions in battery modules?

First, compared with wiring harnesses, NTC thermistor has the advantage of small size, which can simplify the integrated design of CCS and save installation space.

Second, compared with wiring harness, thermistor is directly welded on the CCS, which can respond more quickly and obtain temperature data more accurately.

Third, compared with wiring harness, NTC is more cost-effective, which can improve the cost-effectiveness of CCS while improving the market competitiveness.

In summary, for the pursuit of lightweight and high-density energy storage solutions, the design of CCS significantly optimizes the physical layout of the battery module, reduces the overall weight, avoids redundant wire layout, which is more in line with the solution selection. Considering that CCS has very high requirements for installation space, EXSENSE Electronics Technology Co., Ltd. recommends the use of our CT series SMD type NTC thermistor, which has small size and can well assist the development of battery modules in the direction of integration and miniaturization. The SMD structure of this NTC is suitable for SMT process and can meet the automatic assembly of CCS. The SMD type NTC thermistor of EXSENSE Electronics has a high density of ceramic body, which can improve reliability and effectively optimize the overall performance of CCS.