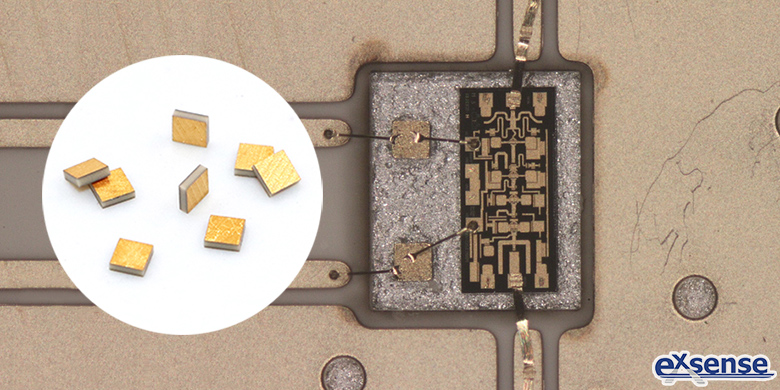

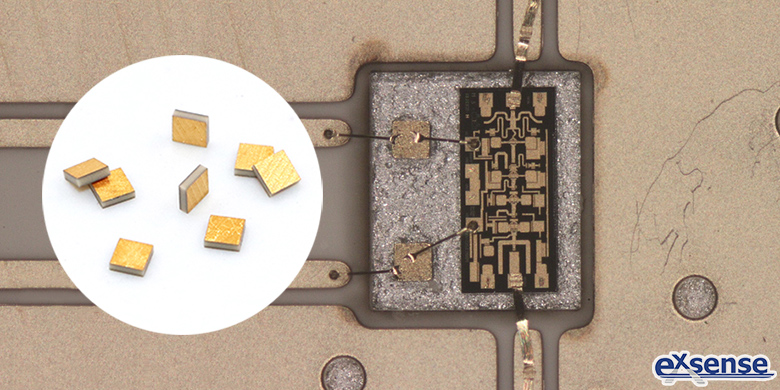

Single layer capacitor produced by EXSENSE Electronics Technology Co., Ltd. is suitable for high frequency, microwave, small and miniaturized occasions, such as microwave power amplifier, hybrid integrated circuit module, mobile phone circuit module, radio microwave communication module, etc. It is high-reliability chip capacitor for commercial and civil applications.

In the existing processing technology, single layer capacitor generally adopts thick film printing technology, layering, cutting and co-firing technology, so there will be hidden quality trouble of not reliable connection between electrodes. Therefore, making a high-reliability single layer capacitor can make its utilization higher. EXSENSE Electronics introduces a single layer capacitor with high resonance frequency and high precision. The specific processing process includes the following steps:

First, the preparation of metallized ceramic substrate in alcohol for ultrasonic cleaning, and then dry;

Second, the upper and lower surfaces of the substrate are metallized by sputtering process under vacuum or gas protection;

Third, the metallized substrate is processed with photolithography, using the negative film obtained after plate making as template, the fine pattern with protective area is made on the metallized substrate by photolithography;

Fourth, the substrate for conventional electroplating, etching, washing process, so that the upper and lower surface of the substrate to form many identical or symmetrical metallized patterns;

Fifth, the substrate is pasted on the basilar plate with thermoplastic adhesive, then cut with a precision cutting machine according to the required size;

Sixth, the cutting basilar plate is cleaned with alcohol or hot water, so that the substrate paste on the basilar plate can separate, the separated substrate is a single layer capacitor with upper and lower metal electrodes;

Seventh, the single layer capacitor is cleaned and dried at 100~150℃ for 15 to 60 minutes. The electrical properties are tested after being placed at room temperature for 24 hours.

Among them, the metallized material used in metallized treatment is a single metal or alloy; In addition, metallized involves sputtering at least one layer of metal material on the substrate.

Metallic materials include at least one of titanium, tungsten, platinum, cobalt, copper, nickel, palladium, gold, tin or at least one of any combination of them.

Photolithography is an exposure and development process similar to photo processing.

The plating material used in the electroplating process is any one of gold, nickel, copper, tin, tin alloy.

The basilar plate is a metal basilar plate of steel or aluminum.

High-reliability single layer capacitor has the following advantages:

First, metal atoms are directly attached to the surface of ceramic medium by vacuum high-energy sputtering under high energy electric field, which overcomes the problems of unreliable intermediate transition layer or perforated connection in thick film printing circuit method. Therefore, the series equivalent resistance of chip capacitor is low and it has good performance at high microwave frequency.

Second, the use of advanced photolithography technology, the chip precision of capacitor is high.

Third, compared with multi-layer chip capacitor, single layer capacitor avoids the current loop formed between dielectric layers, and have lower series equivalent resistance value and higher quality factor when used in microwave.