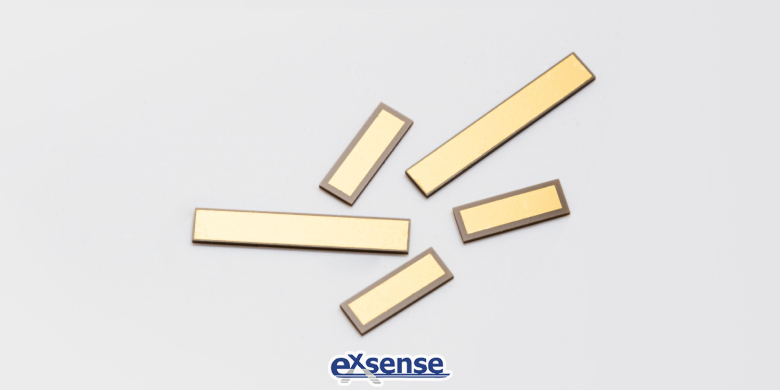

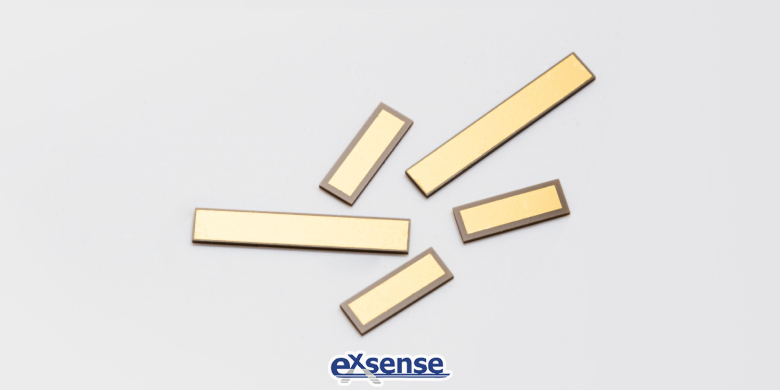

Single layer capacitor has the characteristics of small size, large capacity, solid structure, stable electrical performance, high reliability, etc., which is widely used in electronics, radar, navigation, satellite communications, etc. The grain boundary layer ceramic material of single layer capacitor is a kind of high-performance ceramic material formed by using special micro-structure, namely grain semiconducting and grain boundary insulation. Grain boundary layer ceramic material is used in single layer capacitor due to its characteristics if high dielectric constant and great temperature. But the small size of single layer capacitor, requirement of dicing accuracy are very harsh, especially the adhesion between grain boundary layer materials is weak, the dicing process of traditional single layer capacitor will make the crystal lattice fall off from the ceramic surface, easy to produce porcelain collapse phenomenon, so generally use very expensive and sophisticated imported dicing equipment and imported tools, which production costs are higher.

In order to solve the problem of dicing process of porcelain collapse in the grain boundary layer ceramic, EXSENSE Electronics Technology Co., Ltd. recommends a dicing method of single layer capacitor, which can greatly improve the product qualification rate and dicing quality. The specific process steps are as follows:

First, the surface of the grain boundary layer single layer capacitor with electrode pattern is coated with protective film or protective paint, the thickness is 0.1μm, and put it into a vacuum oven to dry, the time is 30 minutes, and the temperature is 150℃;

Second, the use of automatic film applicator to paste the single layer capacitor on the dicing special film, the viscosity of the dicing special film is 5N/10mm, and the thickness is 0.1mm;

Third, using an automatic dicing machine, put in the single layer capacitor to be diced, and the number of dicing steps is 3 steps for dicing:

Step 1: The dicing height is set to 0.05mm, the dicing speed is 1mm/s, and the spindle speed is 20000rpm;

Step 2: The dicing height is set to 0.1mm, the dicing speed is 2mm/s, and the spindle speed is 30000rpm;

Step 3: The dicing height is set to 0.23mm, the dicing speed is 2mm/s, and the spindle speed is 35000rpm;

Fourth, put the single layer capacitor into the automatic cleaning machine, use two-fluid cleaning, clean and remove impurities such as the protective film or protective paint of the chip capacitor and the residual powder of dicing, then dry it with nitrogen gun;

Fifth, move the single layer capacitor to the automatic film stripping machine, remove the viscosity of the dicing film, and carry out sorting test.

Compared with prior technology, this preparation method has the following advantages:

1. Through the improvement of the dicing process, the crystal lattice of the ceramic capacitor material of the grain boundary layer can be diced neatly, without the phenomenon of porcelain collapse, and the single layer capacitor with neat edges and intact surface can be diced;

2. Greatly improve the product qualification rate and dicing quality, while overcoming the cost problems caused by the use of imported equipment and tools, reducing production costs, which is suitable for industrial production.