IGBT modules generate a lot of heat energy when working, and excessive junction temperature will lead to their performance degradation, such as increased on-resistance, slower switching speed, etc., and even damage in serious cases. Therefore, accurate temperature monitoring and control is essential for the stable operation of IGBT. NTC thermistor is extremely sensitive to temperature changes, and it can monitor the junction temperature changes of IGBT in real time, ensuring that IGBT can operate safely and stably even at extreme operating temperatures.

The specific role of NTC thermistor in IGBT:

1. Accurate temperature monitoring and over-temperature protection

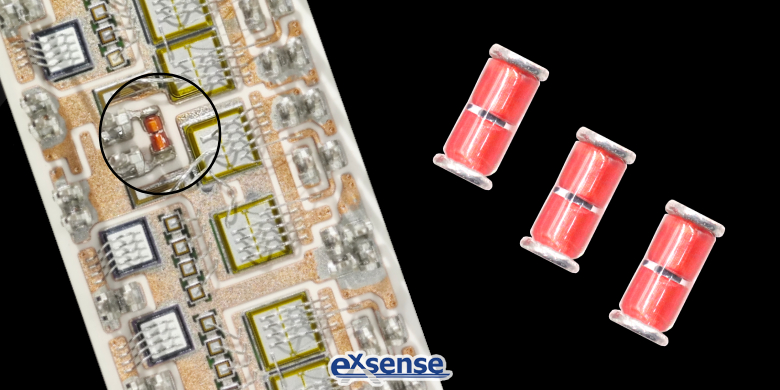

The core characteristic of NTC thermistor is that their resistance value decreases significantly with increasing temperature, which allows it to respond quickly to temperature changes. In IGBT, NTC is usually integrated on the side of the IGBT chip for real-time monitoring of junction temperature. When the temperature exceeds the preset threshold, the change in resistance value of the NTC thermistor is converted into an electrical signal by the external circuit, which in turn triggers the protection circuit to avoid damage to the IGBT due to overheating.

2. Improve the reliability and stability of IGBT

In high-power applications, temperature fluctuations of IGBT module tend to make its performance unstable. NTC thermistor helps with dynamic temperature compensation through high-accuracy temperature monitoring. For example, in the electronic control system of new energy vehicle, IGBT can efficiently adjust the switching frequency and driving current according to the temperature change of the thermistor, so as to maintain stability and reliability, and extend the life of the module.

What are the potential risks if the NTC thermistor is not installed in the IGBT?

If the IGBT does not have NTC set, the module will not be able to sense the temperature change in time due to the lack of real-time temperature monitoring, and the temperature may rise rapidly when overload, poor heat dissipation, etc. When the IGBT continues to operate in a high-temperature environment, its on-resistance will be increased, the power loss will be increased, and the heat generation will be further aggravated, forming a vicious circle. When the junction temperature exceeds the tolerance limit of the IGBT chip, thermal runaway will be triggered, resulting in permanent damage to the IGBT.

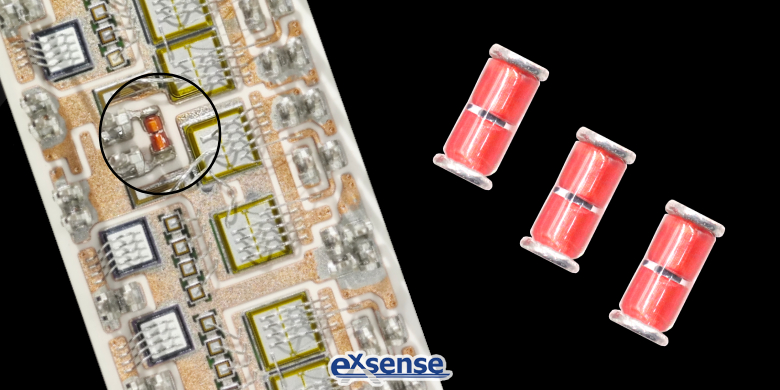

Therefore, with the high sensitivity and high temperature resistance characteristics of NTC thermistor, it can provide accurate temperature monitoring and protection for IGBT modules, which can significantly improve their stability and safety. At present, most IGBT designs will use GT-T series MELF glass encapsulated NTC thermistor, which glass encapsulated structure enables it to maintain stable electrical performance in high-temperature environments, further enhancing the reliability of IGBT.

With the deepening and expansion of the application of IGBT modules in new energy vehicles, smart grids, industrial automation and other fields, higher requirements are put forward for the performance of NTC thermistors. To this end, EXSENSE Electronics Technology Co., Ltd. has launched a self-developed solderable excellent-reliability NTC chip, which semiconductor ceramic structure effectively avoids the potential problem of glass cracking of MELF glass encapsulated NTC thermistor. In addition, the composite electrode layer design of the solderable excellent-reliability NTC chip makes it have great soldering resistance and better meet the assembly requirements of IGBT under complex working conditions. With the rapid development of emerging technologies such as 5G communication, Internet of Things, artificial intelligence,etc., the application scenarios of IGBT will be more extensive, and EXSENSE Electronics will continue to improve the manufacturing process of NTC thermistor and develop new materials to further cooperate with the update and iteration of IGBT module.