In recent years, in response to the market demand of new energy vehicles, IGBT modules have continued to develop in the direction of high switching frequency. This leads to a sharp increase in the heat of the IGBT during operation, which can easily lead to failure. For the high heat generated during IGBT operation, real-time temperature monitoring can be performed with NTC thermistor to provide key thermal management parameters for IGBT.

First, defender of the thermal management security boundary

Over-temperature protection is the most basic and important role of NTC thermistor in IGBT module. IGBTs will produce certain power losses under high-voltage and high-current operating conditions, and most of these losses are converted into thermal energy, resulting in a rapid rise in chip temperature. When the temperature inside the module increases, the NTC resistance value decreases exponentially, and this change is converted into a voltage signal by the acquisition circuit, which is sampled by the ADC and sent to the microprocessor. By comparing the real-time temperature with the preset temperature threshold, the microprocessor can take protection measures such as frequency reduction, current limiting, or shutdown in time to avoid IGBT failure when the risk of overtemperature occurs.

Second, partner of dynamic thermal management

Many key parameters of IGBT, such as on-voltage drop, switching losses, and short-circuit tolerance, are significantly temperature dependent, and the temperature information provided by the NTC thermistor allows the microprocessor to dynamically adjust the operating parameters for optimal performance. When the NTC thermistor detects an increase in the temperature of the IGBT, the microprocessor can increase the gate drive voltage accordingly to compensate for the increase in on-resistance due to the temperature rise, so that the on-loss is maintained within the normal range.

Third, cornerstone of reliability design

In terms of IGBT fault prediction, the temperature historical data collected by NTC thermistor combined with IGBT related performance algorithms can provide a basis for the reliability design of IGBT module. When the thermistor detects an abnormal rise or fluctuation in temperature, the microprocessor can send an early warning signal to the maintenance personnel to check before a potential failure becomes a serious accident. This preventative maintenance strategy not only improves the reliability of the IGBT, but also reduces repair costs and extends the life of the module.

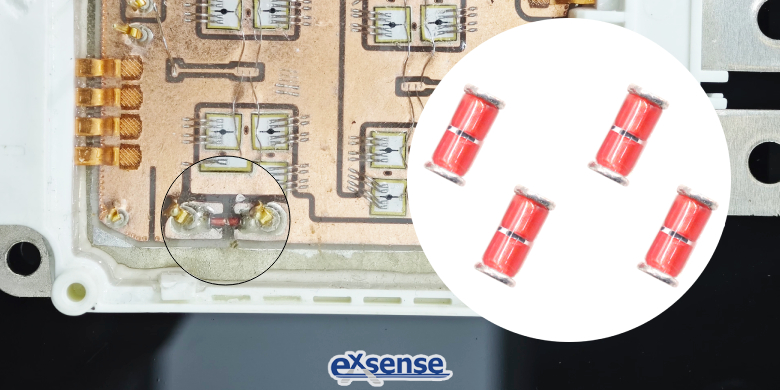

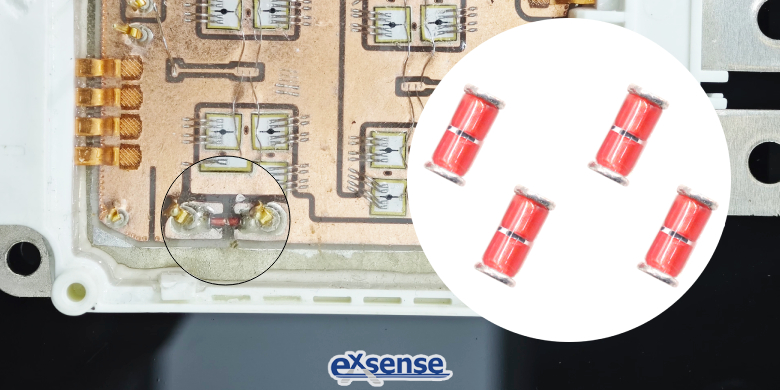

As the core component of IGBT module temperature monitoring and control, NTC thermistor is the key to ensure the smooth operation of IGBT in complex temperature environments. In order to meet the accurate temperature measurement at high temperatures, EXSENSE Electronics recommends the use of GT-T series MELF glass encapsulated NTC thermistor, which glass encapsulation can withstand the working environment of IGBT high temperature section to ensure the stability and accuracy of the temperature measurement process. In addition, the small size of the MELF glass encapsulated NTC thermistor can meet the development needs of miniaturization and integration of IGBT. With the continuous evolution of the IGBT module manufacturing process, EXSENSE Electronics believes that the temperature sensing ability of MELF glass encapsulated NTC thermistor not only builds a defense line of defense for the safe operation of IGBT module, but also provides the possibility for its energy-efficient conversion.